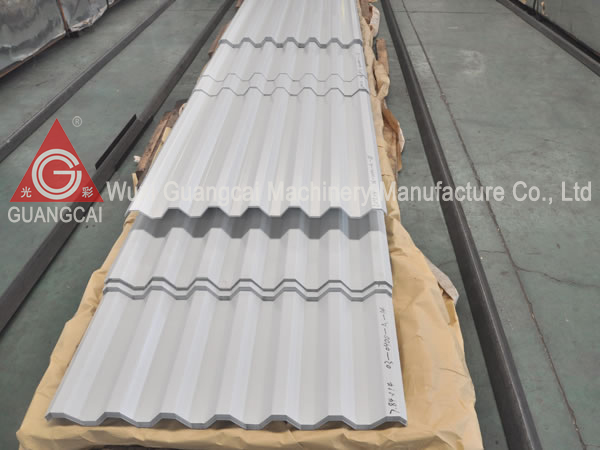

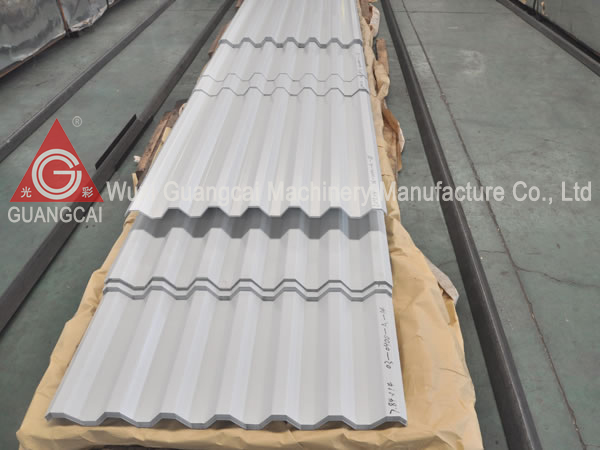

Our GWC35-125-750 roof panel roll forming machine is able to make classic roof panel whose appearance is elegant, artistic and smooth. The corrugations are uniformly distributed, and rib height reaches up to 35mm while the pitch is relatively small. So, the panel is of high strength. Moreover, the roof panel allows reliable overlapping, and it shows excellent resistance to water, typhoon and sabotage.

Advantages

Besides the common features, this product also possesses other outstanding properties.

1. Our roof panel roll forming machine can add one pitch and becomes GWC35-125-875 type. The feeding width is changed to 1200mm accordingly.

2. This machine could work with bending machine to manufacture girderless arch roof.

Processing Flow

Passive decoiling → guided material feeding → roll forming → cut-to-length → offloading

Composition

1. 5T passive decoiler

2. Shape forming machine

3. Hydraulic shear

4. Hydraulic station

5. PLC control cabinet

6. Run out table

Specifications

| Model |

GWC35-125-750/875 |

Note |

| Applicable material |

Color plate, galvanized plate, galvalume plate and aluminum plate |

This machine is customizable upon each customer's requirements and the characteristics of processed material. |

| Feeding width |

1000/1200mm |

| Processing thickness |

0.3-0.8mm |

| Roller material |

45# coated with hard chrome |

| Man motor power / hydraulic station power |

5.5kW / 3kW |

These parameters can be set according to the required production capacity. |

| Rolling passes |

16 |

| Forming speed |

5-15 meters/minute |

| Machine dimensions |

9.5×1.7×1.5m |

| Machine weight |

6.5T |

Related Names

Sheet Metal Forming Machine | Metal Roof Cladding Roll Former | Roofing Sheet Manufacturing Machine