Work Flow

Our glazed roof tile roll forming machine comprises of three parts which are roller table, profiling table and cutter table. The rollers rotate with the cycle chain that is driven by the motor to execute roll forming treatment to the color plate, then the profiling process is done as a result of the vertical movement of the dies driven by the hydraulic cylinder to press the color plate into multiple sections with equal distance, creating an appearance that is similar to glazed tile. Finally, the cutting process is applied to carry out cut-to-length operation to the color plate through the vertical movement of cutters, and the cutters are driven by hydraulic cylinder.

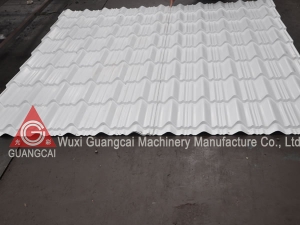

Finished Product

The glazed roof tile has elegant and beautiful appearance, and it is commonly used for buildings in tourist attractions, garden-style factories and more.

Features

1. The glazed roof tile usually has large rib height and high strength. As a result, it may get crushed easily or the paint may be scratched. However, we have made several improvements on relevant dies to avoid these phenomena, thereby guaranteeing the beautiful appearance and precise dimension of the final product.

2. This kind of roll forming machine is able to directly process steel coil whose width is 1000mm, 1200mm or 1250mm. So, for the steel coils bought from the market, there is no need to cut them longitudinally to get desired width. Accordingly, the steel coil is fully used.

3. This is a mature product, and it can be customized if corresponding drawings are provided.

The GWC29-193-965 glazed roof tile roll forming machine is a high quality product, and it is used to make glazed roof tile just as its name implies. The finished roof tile has increased depth and pitch, and the effective area is enlarged accordingly, thus improving the utilization rate of steel.

Processing Flow

Passive decoiling → guided material feeding → roll forming → press forming → cut-to-length → offloading

Composition

1. 5T passive decoiler

2. Shape forming machine

3. Pressing dies

4. Hydraulic shear

5. Hydraulic station

6. PLC control cabinet

7. Run out table

Specifications

| Model |

GWC29-193-965 |

Reference |

| Applicable material |

Color plate and galvalume sheet |

This machine is customizable upon each customer's requirements and the characteristics of processed material. |

| Feeding width |

1200mm |

| Processing thickness |

0.3-0.8mm |

| Roller material |

45# steel coated with hard chrome |

| Main motor power / hydraulic station power |

5.5kW / 7.5kW |

These parameters can be set according to the required production capacity. |

| Forming passes |

17 |

| Forming speed |

2-3 meters/minute |

| Machine dimensions |

7.5×1.3×1.2m |

| Machine weight |

7T |

Related Names

Steel Roofing Tile Machine | Roofing Shingles Making Machine | Interlocking Roof Tile Forming Machine