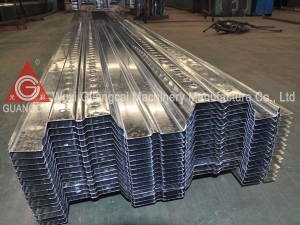

The floor deck roll forming machine contains many models, but they have something in common as demonstrated below.

Features

1. The feeding width of our machine is 1000mm. So, there is no need to slit the steel coils that are directly bought from the raw material market, thereby making full use of the steel.

2. This is a pretty mature product, and redesign process is completely unnecessary for the models that have been fabricated by us, thus largely shortening the production cycle. In addition, the floor deck roll forming machine is customizable.

Processing Flow

Passive decoiling → guided material feeding → roll forming → cut-to-length → offloading

Composition

1. 5T passive decoiler

2. Shape forming machine

3. Hydraulic shear

4. Hydraulic station

5. PLC control cabinet

6. Run out table

Specifications

| Product |

GWC76-344-688 floor deck roll forming machine |

Note |

| Applicable material |

Galvanized plate |

This machine is customizable upon each customer's requirements and the characteristics of processed material. |

| Feeding width |

1000mm |

| Processing thickness |

0.7-1.2mm |

| Roller material |

45# steel which goes through heat treatment and hard chrome plating |

| Main motor power / hydraulic station power |

15kW / 5.5kW |

These parameters can be set according to the required production capacity. |

| Forming passes |

28 |

| Forming speed |

5-15 meters/minute |

| Machine dimensions |

14.5×1.9×1.5m |

| Machine weight |

17T |

Related Names

Decking Sheet Forming Machine | Galvanized Sheet Manufacturer | Corrugated Floor Deck Machine