Contact Us

Wuxi Guangcai Machinery Manufacture Co., Ltd Add.: No. 545, Qianhu RD, Wuxi city, Jiangsu province, P.R. China

|

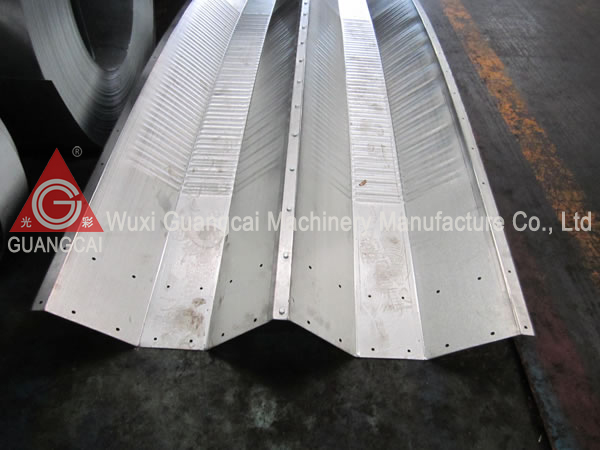

Features 2. The press forming table is able to process color plates with thickness of 0.5-1.5mm, and a power device is outfitted to automatically convey these plates. During press forming step, there is no need to frequently adjust the gap between the rollers even if plate thickness changes, and the coated layer of color plate is well protected from being scratched. 3. The curvature of arch slab is regulated by an assisting handwheel and a counter which are easy to operate. Thus, the product quality and dimensional precision are guaranteed. 4. This roll forming machine has two methods to generate the arch. a. With the help of a three-roll curving machine, a smooth arch is created, and the span reaches 38m. This method is usually used for constructions with large span such as hangar, workshop and livestock building, etc. In addition, a lock forming machine is used to connect the plates, and no bolt is needed. b. The second method is to form the arch by a curving machine. This machine makes partial arch with small span for spire roof tops and ridges, such as garages, retail shops, repair plants, etc. The connection method is screw fixation in the pre-punched holes. 5. The k-span roll forming machine can be designed according to the requirements and drawings provided by our client. Processing Flow 1. 5T passive decoiler 5. PLC control cabinet

Curved Roof Panel Machine | Crimp Curved Sheet Forming Equipment | Arc Roofing Sheet Making Machine

Inquiry Form

|