Features

1. The roller shutter roll forming machine is able to manufacture beautiful and ventilated roller shutter with the help of embossing machine and punching machine.

2. The fabricated roller shutter is very firm, and it is commonly seen in garages, stores, warehouses are other places.

3. This roller shutter roll forming machine could be designed on the basis of customer's requirement and relevant drawings.

Processing Flow

Passive decoiling → guided material feeding → roll forming →folding edges at fixed length and cutting→ offloading

Composition

1. 3T passive decoiler

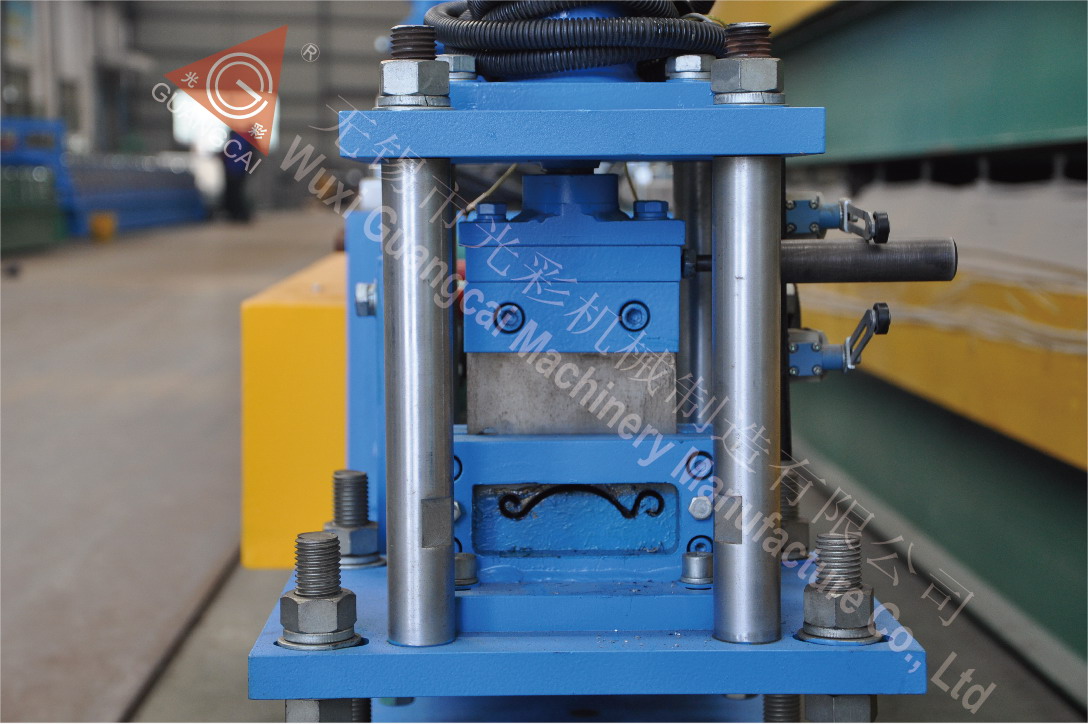

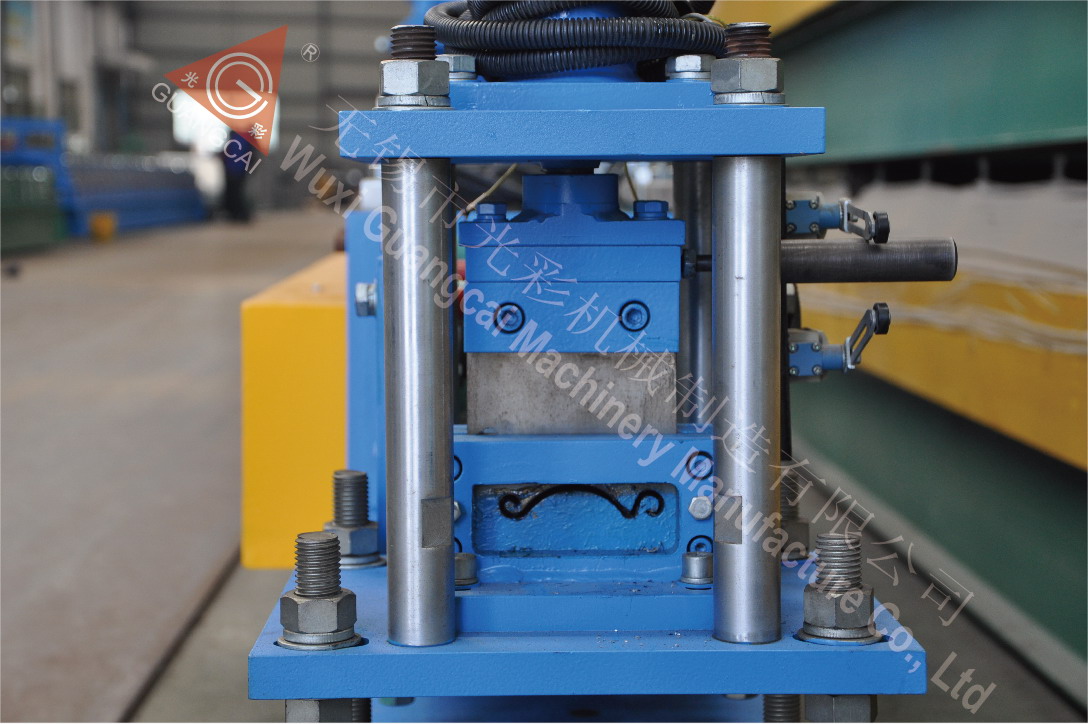

2. Shape forming machine

3. Hydraulic shear

4. Hydraulic station

5. PLC control cabinet

6. Run out table

Specifications

| Model |

GWC17.4-90.5 |

Note |

| Applicable material |

Galvanized plate and color plate |

This machine is customizable upon each customer's requirements and the characteristics of processed material. |

| Feeding width |

140mm |

| Processing thickness |

0.4-1.0mm |

| Roller material |

45# steel coated with hard chrome |

| Main motor power / hydraulic station power |

3kW / 3kW |

These parameters can be set according to the required production capacity. |

| Forming passes |

16 |

| Forming speed |

5-15 meters/minute |

| Machine dimensions |

5.9×1.1×10m |

| Machine weight |

3T |

Related Names

Metal Rolling Shutter Equipment | Industrial Roller Shutter Machine | Blockout Shutter Making Machine