Contact Us

Wuxi Guangcai Machinery Manufacture Co., Ltd Add.: No. 545, Qianhu RD, Wuxi city, Jiangsu province, P.R. China

|

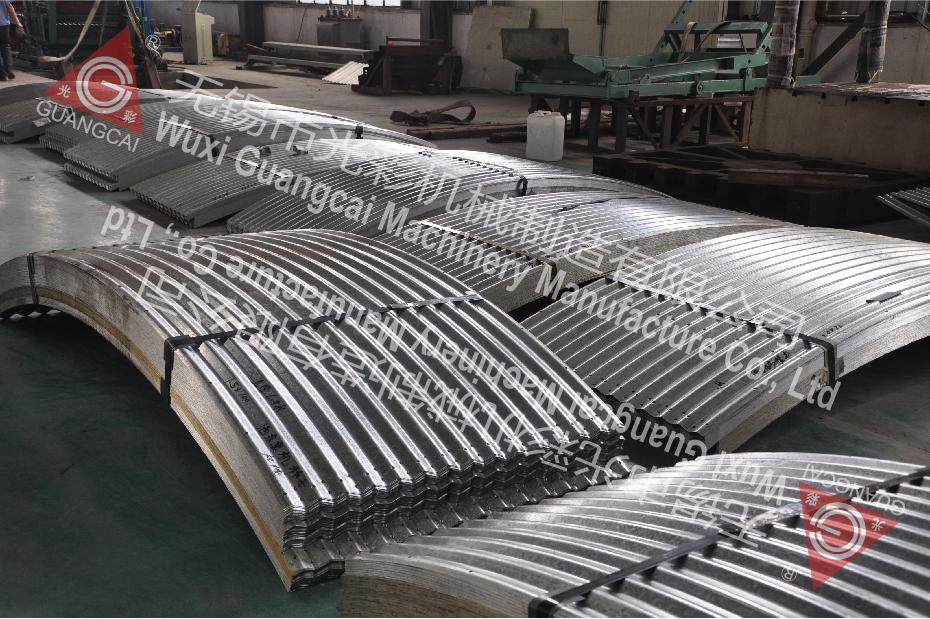

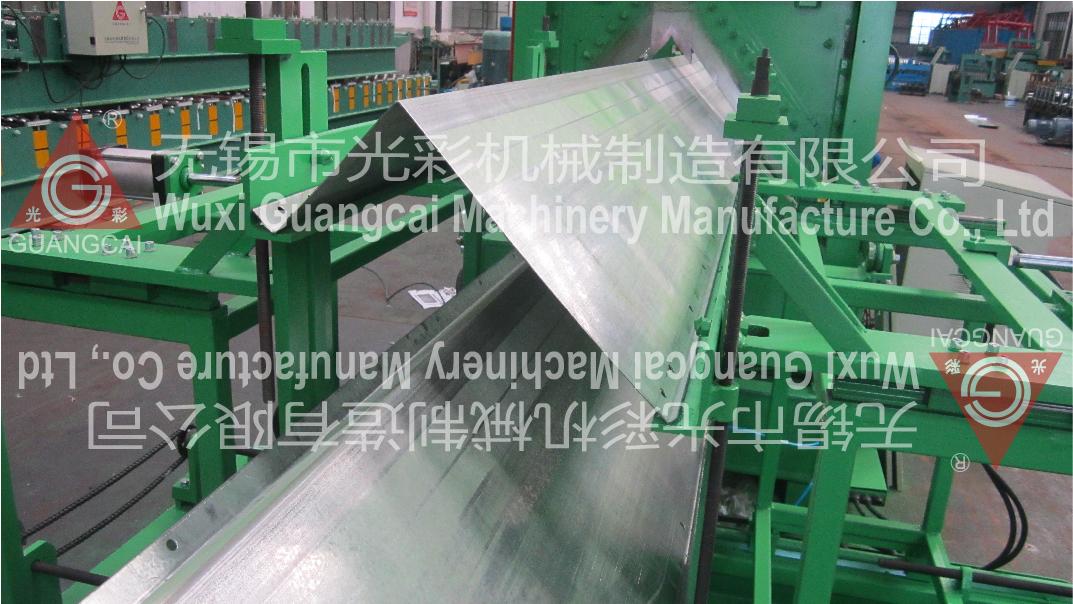

Now, the assembled silo that is composed of galvanized corrugated sheet is widely used for the purpose of commercial grain storage around the world, and our GWC14.5-80-1120 assembled silo corrugated sheet roll forming machine is especially designed to manufacture such steel sheets. Features 2. Our product makes use of rollforming technology to fabricate the corrugations one after another, resulting in released internal stress, reduced spring back effect as well as improved product quality. 3. This corrugated sheet roll forming machine is most popular one among similar products on the market, and it can be tailored to best fit every customer's needs if relevant drawings are supplied. Meanwhile, the production process, including two options, is up to the customer. Patents 1. One feeding device for curved corrugated sheet production line (ZL201020606332.1). It has the advantages of universal application, high automation level, safe and reliable operation, etc. 2. One bidirectional curving machine (ZL201120054585.7). It has upper and lower curving rollers, and the continuous curving method avoids straight edge on both sides of the sheet. As a result, the finished sheet is aesthetic and allows simple assembly. 3. One curved corrugated sheet forming line (ZL201120055257.9). There is a slitting machine at the back end to cut off the extra sheet in the transverse direction (width direction) which is caused by the rolling process, and the cut parts are collected by an automatic recycling device. With a simple structure, this sheet forming line is able to deliver reliable performance, thereby improving working efficiency and lowering labor cost. 4. One three-station punching machine (ZL201120055225.9). It uses a three-station punching die to conduct complete punching treatment to the corrugated sheet. It shows the advantages of high precision, low deviation and simple construction. 5. One curved corrugated sheet shearing machine (ZL201020606306.9). This is a universal device, and it uses the handwheel to adjust shearing angle and height. CompositionThis corrugated sheet roll forming machine consists of several parts, as listed below. 1. 10T hydraulic decoiler 5. Curving machine

Related Names

Inquiry Form

|