Features

1. The folding and roll forming machine produces folded panels that are applicable to make doorframe, file cabinet, electrical cabinet, household appliances, etc.

2. Our machine adopts stepless variable speed drive to adjust final product's specification, and any specification is available but the bottom width should be within 300-1200mm.

3. Holes or notches may be punched on the material first, and then independent bending process can be carried out after roll forming operation is finished.

4. This folding and roll forming machine can be designed according to the drawings provided by our client.

Processing Flow

Passive decoiling → guided material feeding → roll forming → folding edges with fixed length and cutting → offloading

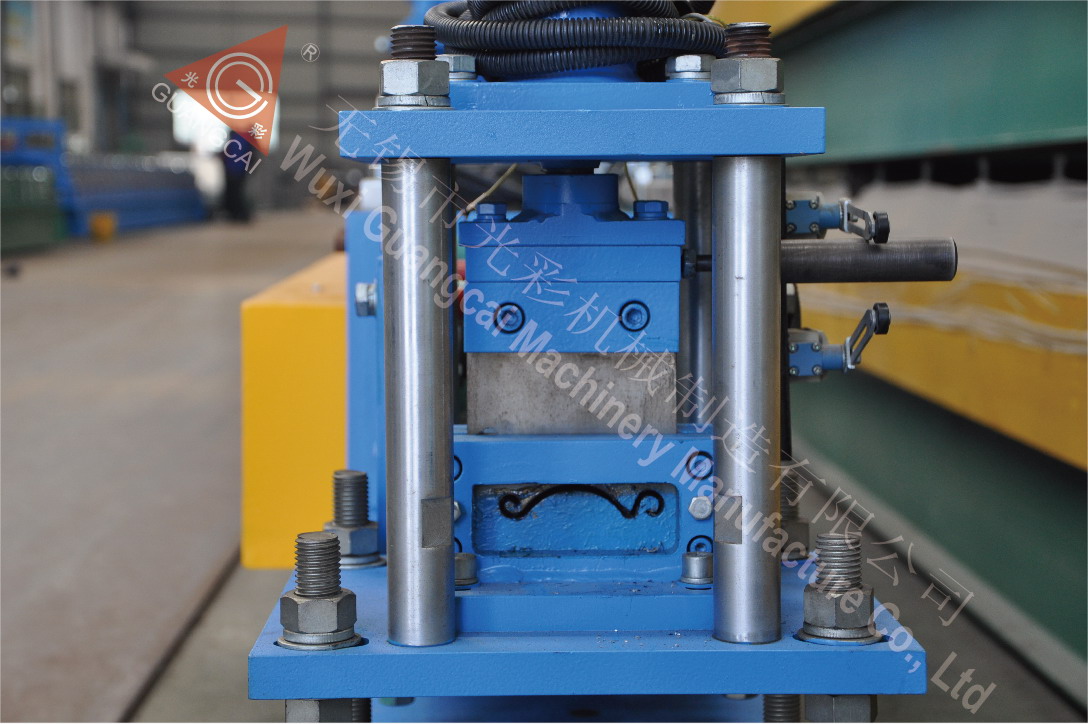

Composition

1. 3T passive decoiler

2. Shape forming machine

3. Hydraulic shear

4. Hydraulic station

5. PLC control cabinet

6. Run out table

Specifications

| Model |

GWC300-1200 |

Note |

| Applicable material |

Galvanized plate and color plate |

This machine is customizable upon each customer's requirements and the characteristics of processed material. |

| Feeding width |

≤1250mm |

| Processing thickness |

0.4-1.2mm |

| Roller material |

45# steel coated with hard chrome |

| Main motor power / hydraulic station power |

5.5kW / 5.5kW |

These parameters can be set according to the required production capacity. |

| Forming passes |

10 |

| Forming speed |

5-15 meters/minute |

| Machine dimensions |

5×1.5×1.2m |

| Machine weight |

4T |

Related Names

Metal Sheet Bending Machine | Metal Manufacturing Equipment | Sheet Metal Forming Machinery